Agronomy, Homepage Slider, Water Quality

Field to Lake Field Day in Paulding County

By Dusty Sonnenberg, CCA, Ohio Field Leader: a project of the Ohio Soybean Council and soybean checkoff.

There is a saying in agricultural drainage: “Farmers pay for field tile every year. The only difference is if they actually have drainage tile in the field or not.” The idea is that there is either an expense being depreciated for the purchase and installation of field drainage tile, or there is a yield hit due to either late planting from wet soils, or saturated soils and water damage to the crop during the growing season due to not having adequate drainage.

In many of the former lake-bed soils found in Ohio, water management is a key to crop production and achieving maximum yields. In certain times of the year, this means getting rid of excess water. In other times of the year, it means conserving as much soil moisture as possible.

Don Johnson, a farmer in Paulding County, Ohio recently hosted a “Field to Lake” field day focusing on the use of water control structures. Johnson’s farm has been in the family for over 125 years, and he has been utilizing both no-till and water control structures on his farm for the past 15 years. “It used to be (before no-till) that when you get ½ inch or rain in the summertime, it would run down the cracks in the soil and out the tile,” said Johnson.

“Now with no-till and these water control structures, we can hold that water back for the crop.” Johnson has 23 of the structures on his farm, controlling water on areas ranging from 15-30 acres each. The structures are sized based on the number of acres and size of tile flowing into it.

Johnson says holding water for the crops in the summer, and holding nutrients in the fall, winter and spring are advantages to using the structures. “My wife was riding in the combine with me three years ago, when we had a dry spring and summer. Over the top of every tile, the crop was taller and she made a comment about the difference from the cab,” said Johnson. “Those roots went down to the water, and the structures held enough back in those areas to be noticeable.”

Water quality is also important to Johnson, and he feels the control structures can make a difference.

“With everything going on with Lake Erie and water quality issues, we need to do what we can to protect the water,” said Johnson. Learning how to manage the structures has taken time, and varies from year to year. “I usually open the structures in the spring to let water out before planting so I can get across to plant and get the crop up, then I close them three to four boards high and leave them that way until I get ready to harvest.

I will open them up if I need to let water out if it is a wet fall, so I can harvest and not cause compaction. Even if you leave a few boards down, it will be dry on top, and still keep water and nutrients back where the roots are.” Reflecting on his experience gained over the years, Johnson feels he could probably close the structures a few more boards and raise the water level a little higher in his fields and still be alright. “I think I could close them a few more boards and get by alright. There would be a little more water for the crops, and more nutrients held back,” said Johnson.

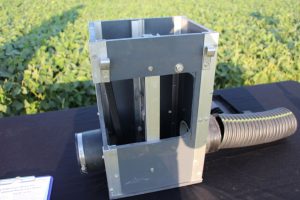

Johnson has two brands of water control structures on his farm. Johnson started with structures made by Haviland Drainage, and he also has some from Agri-Drain. “They are both a little different, but in the end, they work the same,” said Johnson. He suggests farmers considering installing water control structures pay special attention to the quality and the durability of the design. “Each company has a different design. With the freezing and thawing of our soils, it puts pressure on the outside of the structure, and sometimes creates a bind that makes moving the boards a challenge,” said Johnson. “Some styles seem more durable than others.”